Stirling engines: Mechanism and applications for Green Energy Production.

August 9, 2024

Stirlingversal signs a M.o.C with BoAiNeng for system integration

December 6, 2024Exploring gasification advancements with Shanghai Jiaotong University

Stirling engines operate on the principle of cyclic compression and expansion of a working fluid (usually helium or hydrogen) within a sealed system. This cycle involves heating the gas to cause expansion, which drives a piston, followed by cooling the gas to contract it, driving the piston back. The engine’s external heat source and cooling system enable continuous mechanical work.

Stirling engines are versatile in utilizing various heat sources, making them ideal for green energy production. They can harness waste heat from hot flue gases emitted by industrial processes, converting otherwise wasted thermal energy into electricity. Additionally, Stirling engines can utilize biomass as a heat source, where organic materials are combusted to generate the necessary heat. This capability allows for the efficient conversion of renewable resources into clean energy.

By using these diverse heat sources, Stirling engines contribute to reducing greenhouse gas emissions and promoting sustainable energy. Their efficiency, quiet operation, and adaptability to different heat sources make them suitable for various applications, including industrial, residential, and remote power generation, supporting the transition to a greener energy landscape.

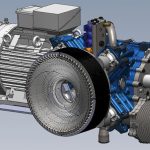

The Stirlingversal engine module offers high efficiency, low emissions, and versatile heat source compatibility, making it ideal for sustainable and adaptable energy solutions.